Resistive and capacitive moisture meters are employed mostly in the grain business. Despite being auxiliary instruments, the needle moisture meter is put into the measured object. In vivo, force affects measurements. The capacitance moisture meter measures moisture straight from the sample.

Capacitive Moisture Meter

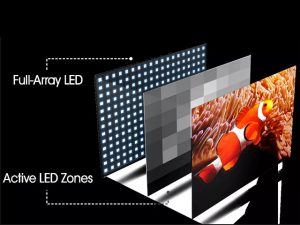

Capacitance measures a conductor’s ability to store electricity. Capacitance depends on the size and form of the conductors, their relative position, and the dielectric between them. When a dielectric is placed in an electric field, it polarizes and weakens the electric field. The dielectric constant is the ratio of reduced to original electric field strength. Air is 1.000585, seed dry matter is 10, and water is 81. When the sample to be tested is put into the sensor, the capacitance depends on the dielectric constant of the sample, and the dielectric constant of the seed sample changes with the moisture level of the seed, so by measuring the capacitance of the sensor, we can indirectly determine the moisture of the tested sample.

If the sensor is linked to a high-frequency oscillation circuit, the change in seed moisture becomes the oscillation frequency, and the mixer produces the difference frequency signal, which is amplified, shaped, gated, counted, and decoded. The seed code displays the seed sample’s moisture percentage. Due to differences in seed shape, maturity, and composition, the density of seeds of the same quality in the sensor is also varied, causing a change in sample height and dielectric constant, which affects measurement accuracy. Before measuring the seed moisture of different crops and kinds, the instrument should be calibrated according to high, medium, and low standard moisture levels.

Within a range, seed moisture was linear. For example, onion seed moisture is linear at 6 to 10 percent, so measurement findings are more reliable when both are linear but not at 2 to 6 percent or 10 to 14 percent. When preparing a standard moisture sample, the difference should be minimal. Capacitance changes with temperature, but the thermistor correction on a capacitive moisture meter doesn’t change the results much.

A cup moisture meter measures capacitance. Turn it around to make the sample consistent, then measure the capacitor for moisture. The moisture meter range is 14–22%. Calibrate each sample in an oven before testing (that is, use an oven to make a standard moisture content and then adjust the parameters of the moisture meter to correspond to the corresponding values of the oven).

Advantage:

Capacitance moisture meters are easy to use, don’t require crushing grain samples, and display data to one decimal place.

Shortcoming:

It is temperature-and uniformity-sensitive. Moisture is almost non-existent at 0 °C. Same-sample uniformity and moisture levels vary. When evaluating grains with over 22% moisture, inaccuracy is significant and repeatability is poor. Above 10 °C, the data can be repeated. Market pricing is 200-500 USD.

Resistance Moisture Meter

The resistance moisture meter is also known as the pin-type moisture meter. The grain business prefers two pins. Resistance moisture meters detect moisture by measuring resistance. The tested sample is resistant equivalent. High moisture reduces resistance, and low moisture increases it. Simply put, it is Ohm’s Law: I = R (resistance equals voltage divided by current).

Moisture in seeds increases conductivity. In a closed circuit with constant voltage, current intensity is inversely proportional to resistance. If the seed is linked to the circuit as a resistance, the lower the water content, the higher the resistance and the lower the current intensity. Seed wetness and current intensity are positively correlated. As long as standard samples have different moisture content, the relationship between the standard moisture content and the change in current can be engraved on the electric meter; that is, the scale of the electric meter can be converted into the scale of the corresponding moisture, or converted through the gate circuit and displayed by the digital tube, and can be read directly. Moisture-out percentage.

Seed moisture and current intensity are not linear in a specific range, and the meter’s scale is mismatched. Due to the internal and external structure of each seed, the amount of current varies, so the scale lines of different seeds are different, or turned into digital display moisture percent. Temperature affects resistance. Changing temperatures need temperature compensation when monitoring seed moisture. Some grain moisture analyzers are calibrated at 20°C. Because resistance decreases and current increases as temperature rises, 0.1 percent of moisture should be deducted for every 1 degree Celsius above 20°C. When the temperature is below 20°C, add 0.1% 25 moisture for every 1°C. No temperature correction is needed with the advanced moisture meter’s thermal compensation approach.

Advantage:

The utility model has the benefits of simple structure, easy carrying, efficient detection speed, no need to process the tested samples, and low price.

Shortcoming:

Such products lack precision, have a limited moisture range, significant test errors, and must be calibrated. Temperature, the environment, and the contact area can impact it. Domestic needle moisture meter goods are likewise uneven and can only be utilized as an auxiliary instrument.