Chromatic aberration exists in every aspect of life. It can be easily distinguished with the help of the naked eye, while in some instances, a professional instrument may be necessary. Colorimeter functions to differentiate colors. In most cases, a colorimeter must be used to measure the color difference value to compare a product’s color to that of a standard product.

The color difference generally focuses on the lab value, and the color difference ΔE value is also obtained through the Lab value:

- The luminance (L) axis displayed black and white, where the value for black is 0, and the value for white is 100.

- The A axis is positive for the red color, whereas it’s negative for green and zero for neutrals.

- The B (yellow-blue) axis’s positive value is yellow, its negative value is blue, and its neutral value is 0.

Any type of lab scale can be used to describe any color. These scales typically have as the identifier, and Δ can be used to show the color difference between the sample and the standard sample.

- The positive value of ΔL indicates that the sample is lighter than the standard. Similarly, a negative value indicates that the sample is deeper than the standard.

- A positive value of Δa indicates that the sample is red compared to the standard sample. A negative value shows that the sample is green.

- If Δb is positive, the sample is more yellow than the reference sample, and if it is negative, the sample is blue.

ΔE represents the lab color difference, where ΔE is the total color difference of the sample. However, it cannot display the direction of the color difference of the sample.

What are the differences between the different types of colorimeters?

A handheld colorimeter is able to read color difference data directly. It cannot work when connected to a computer unless the software is installed. Furthermore, it’s easy to use but offers mediocre accuracy. It is widely used in the general field of color management.

A portable colorimeter can directly read the data and be connected to a computer with software. It’s small and portable with excellent precision and at a reasonable price.

Benchtop colorimeter:

It has no reading display available. A color measurement and matching software is utilized for connecting with a computer. It offers significant accuracy in color measurement and matching functions. However, it’s big and quite expensive.

Colorimeters can be divided into two categories according to their working principles.

- Photoelectric integrating colorimeters

- Spectroscopic colorimeters.

Photoelectric integrating colorimeter:

It takes integral measurements in the visible wavelength region while illuminating the sample with a conventional light source. Common names for it include spectrophotometer and precision colorimeter.

A specialized microcomputer system can provide the color difference value between the tested samples as well as the tristimulus value and chromaticity coordinates of the color of the transmitted or reflected object.

Spectrophotometer:

The spectrophotometer receives the reflection spectrum of the object’s surface by measuring the relative spectral power distribution of the reflected light of the object. Later, it’s weighed and multiplied by the tristimulus value of the CIE spectrum. Once the integration is completed, the tristimulus value, color coordinates, difference, and other parameters of the surface color sample are acquired.

The spectrophotometer consists of the following components:

- Illumination

- Observation system

- Spectroscopic system

- Photoelectric detection system

- Circuit control system.

Things you need to know when buying a colorimeter:

Colorimeters work by evaluating color by six different factors. Any variation in the factors can result in color data alteration, which results in differences between the obtained values by two identical samples or different colorimeters.

- Instrument lighting method: The choice of the colorimeter’s lighting setup will significantly affect how the color information is recorded. Currently, diffuse/8° spherical instruments and 45°/0° or 0°/45° instruments are the most often used colorimeter lighting techniques. The selected choice will primarily depend on the sort of sample used.

- CIE light source: The type of light affects the measurement of color by the color meter. Generally, colorimeters can work with various light sources such as tungsten, cool white fluorescent, average daylight, and noon light. The same type of light should be used when evaluating the color consistency across samples.

- CIE standard observer angle: Two standard observer types are available: i) 2 degrees in 1931 and ii) 10 degrees in 1964. Both of these are fairly identical to each other but have enough differences to influence the color data. It’s essential to use the same standard observer for each sample.

- Color spaces: A variety of color measurement systems are available. At present, five color spaces are approachable, namely CIE XYZ, CIE Yxy, CIE L*a*b*, CIE L*C*h, and Hunter L a b. Each of these scales has three numbers, but each one is chosen randomly. In order to establish a consistent standard amongst samples, it is crucial to use the correct color space for your samples and to do so consistently.

- Sample Preparation: Accurate color data can only be obtained with careful sample preparation. This is crucial since human factors could lead to inconsistent measurement results. Consequently, it is necessary to create uniform sample preparation techniques.

- Sample measurement: Multiple factors, including sample position, sample view area, measurement mode, and the number of average sample readings, are important for sample measurement. Steps must be taken to ensure minimum sample variability.

Theoretically, a consistent color measuring system can be made using any colorimeter to assess a sample’s hue. Consistency can be impacted by variations between colorimeters, though. You must pick a colorimeter that meets your requirements for measurements. The capacity to compare samples at any point of the product development or manufacturing process will be optimized by consistent measurement parameters, providing you with the data you require.

A colorimeter can be chosen to simplify the color measurement process and avoid any measurement errors. It requires highly integrated measurement, automatic sample averaging, and appropriate measurement modes to abolish the need for manual sample preparation.

What is the difference between the application of a colorimeter and spectrophotometer?

Spectrophotometers and colorimeters are often used for the same purpose. So, what separates the two of them?

What is a “colorimeter” and what is a “spectrophotometer.”

A colorimeter is used to measure the color difference between two samples, but the accuracy is questionable. In most cases, it is impossible to give an exact color’s L, a, or b value, but it is possible to give the difference in color between two samples, often the standard and the sample.

On the contrary, the spectrophotometer offers high precision and the setting of the pre-positioning plate. Consequently, the need to use standard blackboards and whiteboards in the calibration process of traditional colorimeters and colorimeters is omitted. The robust built-in software has a significant number of industry- and application-specific indicators, all the essential color equations, and standard light sources for various jobs.

- Design principle

The spectrophotometer follows the spectroscopic approach, whereas the colorimeter employs the tristimulus approach. Colorimeters have high precision, and the spectrophotometer can measure SCI and SCE simultaneously. It is appropriate for complicated color analysis because it can measure reflectance at each wavelength, although it is relatively expensive. The tristimulus colorimeter’s advantages include its tiny size, exceptional versatility, and ease of use.

- Measurement principle

The colorimeter can analyze the color difference between the sample and the tested product. It produces three sets of data of CIEL; a, b, and c followed by four sets of color difference data of △E, △L, △a, and △b after calorimetry. The spectrophotometer can determine the reflectance curve of each color point, unlike the colorimeter. Spectrophotometers can simulate a variety of light sources, while colorimeters generally have only one or at most two simulated light sources.

- Light source

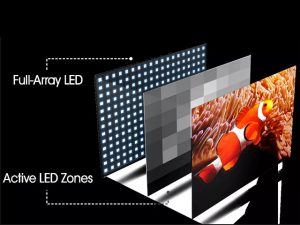

When choosing a light source for the color measurement device, stability, light source directionality, longevity, and the reliability of the final spectral curve should all be taken into account. Currently, xenon and LED bulbs are used as the majority of light sources.

Xenon lamps are the primary source of UV light source measurement, which emits a short high, intensity arcs. However, repetitive generations of equal intensity arcs are difficult. The high-voltage oscillation excitation circuit needed for the xenon lamp light source is rather intricate, and maintenance is extremely difficult. The replacement cost is higher because the entire set of capacitors must be replaced in addition to the bulb.

LED lamps are technically and economically the most appropriate for the current standard colorimetric devices. Portable equipment must be lightweight, power-efficient, and simple to maintain and use. The full-band balanced CLED light source is used in the color spectrum measurement device, which means that there is no need to worry about the light source needing to be changed out too frequently.

Colorimeters are generally used for sample comparison and determining color differences. The basic components of a spectrophotometer are:

- Essential color equations

- Common light sources

- A wide variety of sector and application-specific indicators.